Model No.︰-

Brand Name︰fushun EJET

Country of Origin︰China

Unit Price︰US $ 3000 / set

Minimum Order︰1 set

This Stainless-Steel Magnetic Separator is unique Neodymium Rare Earth magnetic roller that produces an ultra-strong magnetic force to attract even the micro iron or para-magnetic weakest magnetic materials ( such as silica , sulfur dioxide , stainless steel ) . The strength of the magnetic field is far greater than standard magnetic separators, extending the separation capabilities from just removing ferrous and strongly magnetic materials to materials that have a very low magnetic susceptibility.

for micro iron or para-magnetic material(such as silica, sulfur dioxide, stainless steel ) extraction .besides this also be widely used in abrasive materials, plastic, silicon sand, medicine, glass, founding, building material, the special material ,metal and electronic products grade, resources recovery and so on.

This extrodinary performance magnetic rollers are ordinary be installed above the conveyor belt, vibratory feeders and inclined planes to attact small and large ferrous and paramagnetic material .

Feature of Ultra powerful dry high intensity roll type magnetic separator:

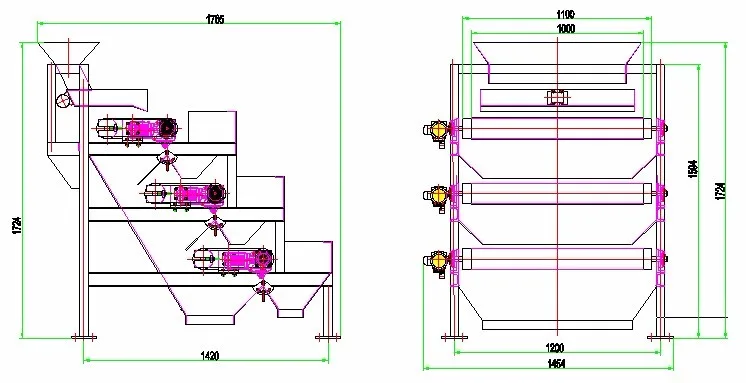

Assembly drawing for magnetic rolls separator

Applcation of dry type mineral ore sand process magnetic rolls

Remove micro iron or para-magnetic material to improve the material grade,typical application include

Working principle

This extraordinary performance magnetic rollers are ordinary be installed above the conveyor belt, vibratory feeders and inclined planes to eliminate the tramp ferromagnetic metal to get the purify products.

About us

With well-equipped professional engineers and strong technical force, Ejet have been in magnetic metal solution for 12 years, we cooperate with superior suppliers (Nord/SEW/Siemens /Schneider)to keep our quality,the test of materials is free if you are interested in our machine, strict quality checked for every machine before packing, engineers available to service machinery overseas, inaddition, there is not only after sales service support, but also technology support, "keep improing, persuing excellence" would be keep forever.

Our main products are eddy current separator, suspended magnetic separator,lifting magnets,etc.

With good quality, reasonable prices,our products are extensively used in solid waste treatment, metallurgical mine, power plants, coal mining and other industries. The products have been exported to the United States, Canada, Japan and Australia.

FAQ

In order to recommend the most suitable model , pls kindly let us know the situation of mineral ore sand that will processed for ferromagnetic material removal

the information should ncluded the sand`s composition , content of each somposition , size , handling capacity for per hours & the usage of the material after processed

Most suitable machine would be recomended to you according to your informations.Any question , please contact with us no hesitation ,will much highly appreciated .

Fushun Ejet Magnetic Equipment Co., Ltd

NO.23 Pacific Industrial City,Economic Development Area

Fushun City,Liaoning Province,China

Ms Jasmine Song

CELL: +86 15242300557(Wechat/whatsapp)

SKYPE: luckjasmine86

EMAIL:jsyy@sino-magnets.com.cn

Price Terms︰ FOB/CNF/CIF

Payment Terms︰ TT / LC / DP / DA

Packing︰ nude in container or packed by wooden case

Lead Time︰ about 45 days upon received the deposit